Recycled fiber vs virgin fiber in packaging

Businesses big and small are doing their part to reduce waste and limit greenhouse gas emissions by working toward a more sustainable future. While there are many ways to advance sustainability, one of them is for companies to adopt better, more responsible packaging solutions.

A common thought is that packaging made from 100% recycled material is the optimal choice. But in fact, the need for virgin fiber, or fresh material, is essential and also supports sustainability.

How virgin fiber complements recycled fiber

You can't have a sustainable, circular economy without a constant supply of high-quality virgin fiber enabling the existence of recycled fiber.

WestRock's virgin fiber, or fiber not previously used to produce paper or packaging products, is sourced from responsibly managed forests. We also partner with organizations like The Center for Heirs' Property Preservation® to drive social equity through sustainable forestry.

Alternatively, our recycled fiber comes from used paper and packaging collected through either WestRock's dedicated recycling plants or from partnerships with national haulers. While it would be ideal to infinitely reuse fiber-based products, the reality is that the fibers in paper and packaging can only be recycled between five and seven times before it becomes unsuitable for most products.

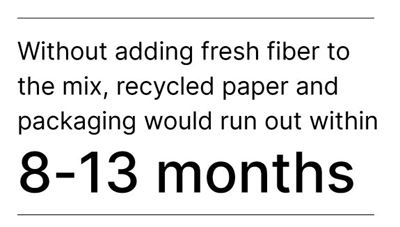

Each time recycled fiber is processed, the individual strands drop in quality and strength. Without adding fresh fiber into the mix, recycled paper and packaging would run out within 8-13 months1. Therefore, virgin fiber remains vital to a sustainable, circular packaging operation.

Supply chain inefficiencies, shifting costs and transportation demands are also factors. Making an environmentally friendly packaging choice can’t be done simply by deciding between recycled or virgin sources. Instead, consider whether the decision makes sense for environmental objectives and whether the supplier supports sustainability throughout the papermaking process.

How virgin fiber benefits the circular economy

Sustainable forestry is at the heart of WestRock's operations. Planting trees, harvesting them at the right time and converting them into responsible forest products are crucial to a more sustainable future.

WestRock works with partners who consider sustainability every step of the way and operate in areas that are forest positive— that means planting more trees in the procurement basin than what they harvest, ensuring the environment remains healthy and productive.

Flourishing sustainable forests confer significant ecological benefits alongside virgin fiber production. Sustainable forests can directly contribute to:

- Clean water

- Wildlife diversity

- Carbon sequestration

- Recreation: Forests often serve as vibrant recreation areas for local communities, and WestRock has invested in providing access to urban greenspaces.

Beyond these upsides, responsibly harvesting forests is also good for the landscape's long-term health. When a forest becomes overcrowded with trees, the lack of space, water and sunlight means the canopy and understory struggle to achieve productive growth. Without virgin fiber harvesting, maximizing regeneration and biodiversity in forested environments can be difficult, and fire hazards can also arise.

How we're driving fiber-based innovation

Virgin fiber is essential to a sustainable, circular economy. WestRock's forestry practices help to ensure these resources achieve the most benefit:

- Through collaborative relationships with landowners in the U.S. and abroad, we provide extensive education, guidance and support for sustainable forest management.

- We create economic incentives for private landowners and family tree farmers to continue using their land for working forests, ensuring these vast regions provide crucial carbon sequestration, freshwater supplies and diverse habitats.

- We're driving innovation through smarter fiber-based packaging solutions and closed-loop programs alongside sustainable partnerships with companies like Kraft-Heinz, Grupo Modelo and Swiss Chalet.

Reducing waste and emissions with collaborative ideas

WestRock partners with the world's leading companies to deliver packaging solutions that carefully consider natural resources and enhance our response to the changing marketplace as well as consumer interests.

We helped support Kraft-Heinz sustainability goals and better reflect consumer demand by developing a recyclable paperboard sleeve for its multi-can products. This no-glue innovation uses 50% less material than a traditional wraparound box while reducing CO2 emissions by 18.7% compared to the equivalent shrink-wrap design.2

Similarly, we partnered with iconic Mexican brewer Grupo Modelo on implementing CanCollar® – a paperboard-based alternative to plastic rings for beverage multipacks. Durable enough to withstand the moist conditions inside a brewery, this forward-thinking design is expected to reduce plastic waste by more than 100 tons annually.3

Developing closed-loop systems with General Motors

Commercial operations are also vital to the recycling process, with the right approach helping to ensure natural resources are used to their maximum potential. WestRock recently helped General Motors establish a closed-loop recyclable virgin fiber packaging system, highlighting how virgin and recycled sources work together to produce sustainable outcomes.

As a one-stop supplier and recycling partner, we produce specially designed fiber-based products for General Motors and pick up and move into our mill system almost 17,000 tons of recyclable material per year across just five of GM’s plants.

With the reclaimed virgin materials soon beginning a new life as recycled products, this program also supported GM’s Zero Waste goal to divert greater than 90% of their operational waste from landfills and thermal processing facilities by 2025. WestRock is honored to support its customers’ progress toward their sustainability goals while creating less waste and enabling a circular paper-based economy.

How to choose the right fiber mix

WestRock offers a diverse range of packaging options including those that use 100% recycled fiber. A range of questions can help businesses select sustainable packaging that also achieve business objectives and fulfills environmental needs:

- Know what's driving the need: Consider the reasons for choosing a fully recycled product. From customer expectations to industry standards, motivation might determine which product makes the most sense.

- Consider the intended use: Recycled paper-based products can be a great choice but the intended application matters. Strength and durability demands influence the ideal packaging decision.

- Explore options: While many of WestRock's products are 100% recyclable, others feature a combination of virgin and recycled fiber to improve longevity and performance. Get to know the range of options.

- Drive innovation: If there isn’t a 100% recycled option, there may be an opportunity to create an innovative product. WestRock's research and development team can help customize a packaging solution.

Choose the ideal fiber-based packaging

The ultimate target for WestRock and its customers is a more sustainable future. Yet it's imperative to understand that achieving this is not necessarily a question of virgin or recycled fiber. Instead, it's about how we can leverage both virgin and recycled fiber to elevate environmental benefits and serve customers.

At the intersection of innovation and sustainability, our fiber-based packaging enables consumers to make more eco-conscious choices. As we continue to innovate boldly and package sustainably, our comprehensive solutions can help businesses achieve objectives. Visit our Insights page or contact us to learn more.

1. Facts & Trends: Fresh & Recycled Fiber Complimentarity, NCASI

2. Lower CO₂ footprint of 18.7% on the Heinz Eco-Friendly Sleeve 4-pack design, while the CO₂ footprint is reduced by 11%, based on weighted average annual volume 2020 for all Heinz multipacks. As verified by an independent LCA study that has been externally reviewed and which follows the ISO guidelines.

3. Based on 2x3 standard can pack format, and plastic ring finished package weight of 8 grams/pack across 12 million packs.